A partnership between aircraft manufacturer Airbus and additive manufacturing service Materialise is now producing in-cabin parts. A divider with an organic form, it is Airbus’ first use of 3D printed parts in plain sight within its commercial aircraft.

In 2015 Airbus and Materialise entered into a partnership to create 3D printed parts for aircraft. Going all in on proving the viability of additive manufacturing’s benefit to aerospace, the partnership quickly bore fruit in the news that the 3D printing firm gained a raft of certifications enabling them to product airworthy parts.

This announcement went hand in hand with notice of Materialise beginning production of plastic parts for Airbus’ A350 XWB aircraft. These parts, however, were for the behind-the-scenes workings of the aircraft, where function takes precedence over form.

Fast forward three years, and the relationship between the companies has taken another step, this time focusing on the fit and finish of in-cabin upgrades to a tight timeline.

3D Printing Airbus Cabin Dividers

Passenger liners can remain in operation for many years, and throughout that lifetime can see multiple refreshes to their interiors. That means replacing wall panels, seating and all manner of other passenger facing elements.

These retrofitting operations are a delicate balance between the aircraft manufacturer, the authorities overseeing the vehicle’s airworthiness and the airlines with their own specific branding and cabin concepts. For the manufacturer, it’s a process that necessitates quick turnarounds on small batches of parts.

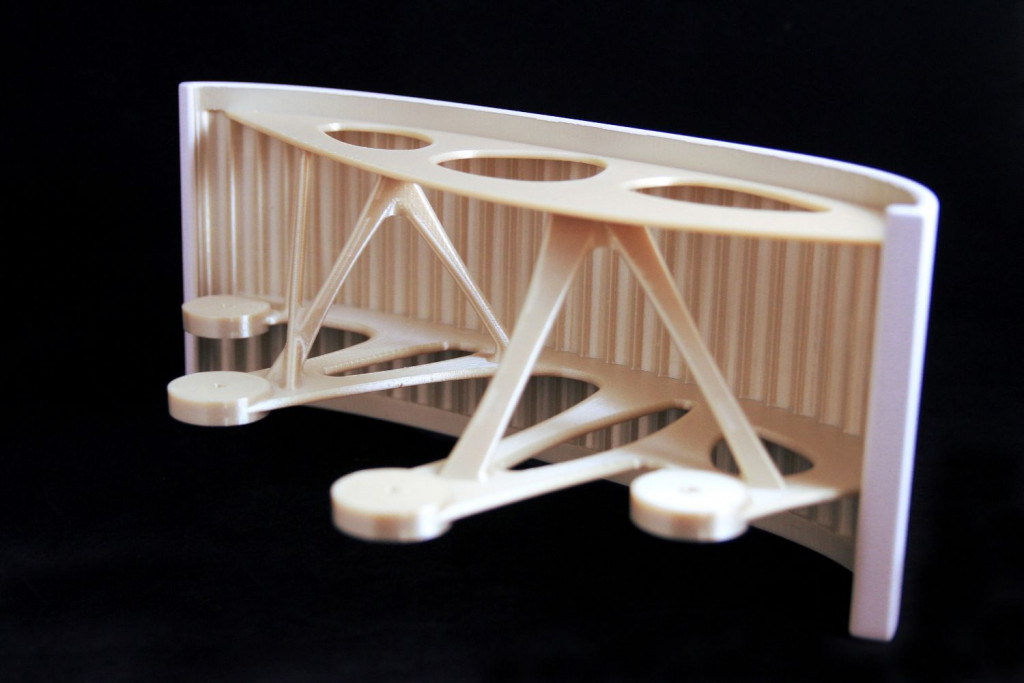

Airbus and Materialise’s partnership came to bear in a project retrofitting Airbus aircraft for Finnair. One of the parts to be replaced was the spacer panels — curved sheets adjoining structural armatures. Materialise’s Certified Additive Manufacturing service produced the parts, which were designed to be a light as possible and adhere to a full bionic design specification by Airbus.

The resulting panels, printing using FDM 3D printing tech by Materialise, are not only of sufficient strength and fit for the job, but possible to finish to in-cabin standards — i.e. treated with flame retardant materials and finished to integrate seamlessly in the existing cabin aesthetic.

For Airbus, the part is a first. And yet another exciting example of the proliferation of 3D printing in aerospace.

Source: Materialise

Website: LINK