Big Air meets Big Printing. BigRep and Etihad Airways Engineering announce plans to collaborate on developing next generation additive manufacturing solutions for the aerospace industry.

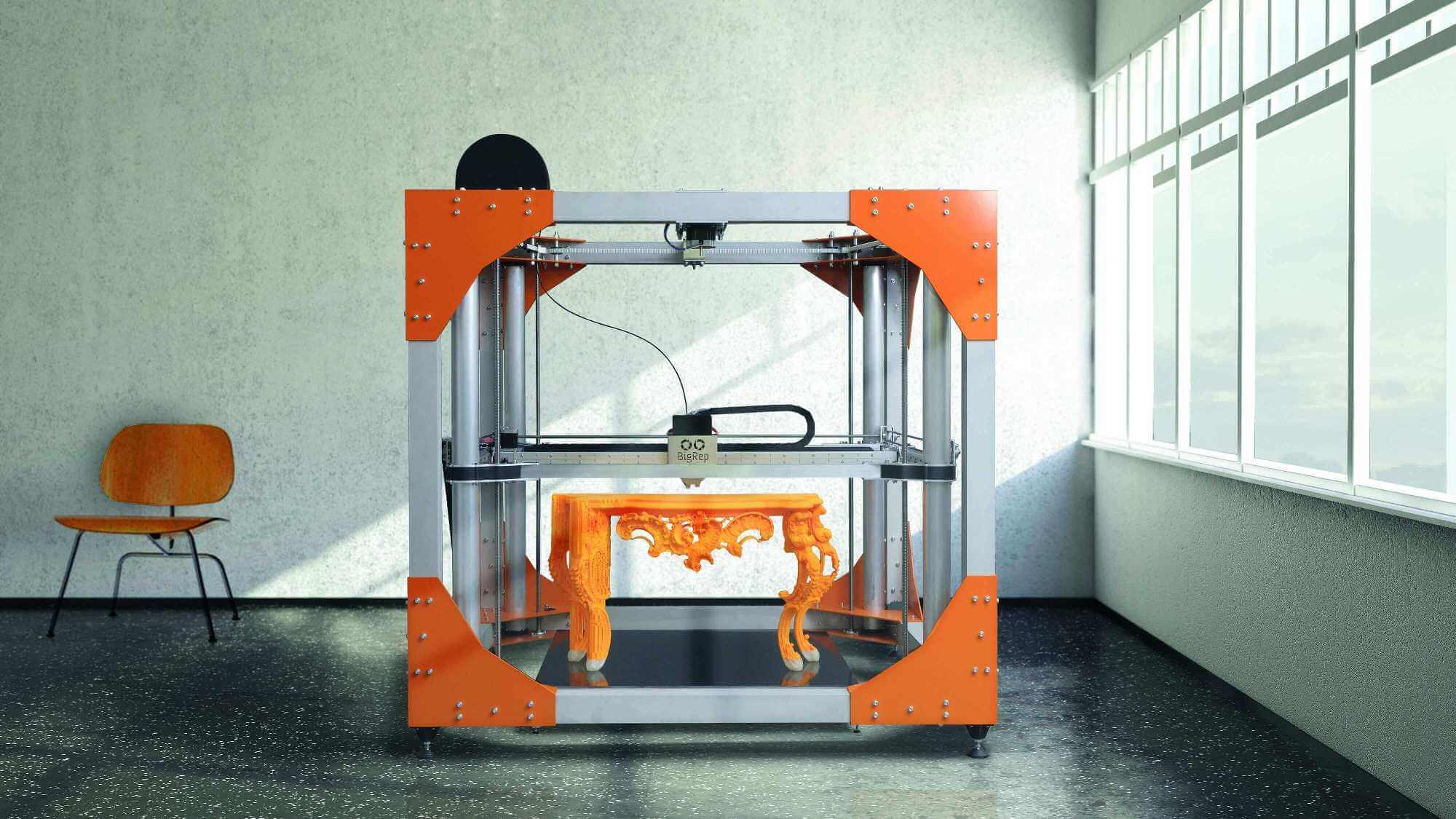

Since it was first launched three and half years ago, 3D printer manufacturer BigRep has quickly become a world leader in large format 3D printing technology. Today, they enter a new market by partnering with an industry leader in the aerospace industry.

BigRep and Etihad Airways Engineering have announced they are collaborating on a roadmap for the development of the next generation of Additive Manufacturing (AM) solutions for aerospace applications.

The companies seek to employ new approaches to realize the full potential of 3D printing for the production of cabin parts. The goal of the partnership is to accelerate the use of 3D printing in the aviation sector, with a focus on cabin interior parts for new aircraft, as well as for the retrofit market.

Etihad Airways Engineering will leverage its experience around the aircraft cabin lifecycle and its drive to develop novel cabin concepts that will be additively manufactured.

“Etihad Airways Engineering and BigRep share a vision to bring the 3D-printed cabin into production, together with our partners,” says Berhard Randerath, Vice President Engineering, Design & Innovation at Etihad Airways Engineering

“Our goal is to enable 3D-printing technologies for cabin parts – be it on new aircraft programmes or for retrofit installations – to serve our airline customers with innovative and smart solutions.”

Etihad Airways Engineering a Perfect Fit for BigRep

Berlin-based BigRep, which provides hardware, software, materials and services for large-scale 3D printing, sees this partnership with Etihad Airways Engineering as a logical step towards becoming the global leader in the digital manufacturing market.

“We believe that Etihad Airways Engineering, with its expertise, is the perfect fit to cooperatively shape the industrialisation of AM for the aviation industry, ” says Stephan Beyer, Interim CEO & CFO of BigRep GmbH.

“We believe that we offer the best additive manufacturing solutions today with our BigRep equipment, but to unfold the full potential of our technology for the aerospace sector, we have to jointly certify new aviation materials and establish specific AM design and engineering guidelines in parallel.”

Already, the partners have identified a need for a wider spectrum of polymer materials which can pass the aerospace certification process.

Currently, one of the biggest factors preventing the use of additive manufacturing for aircraft cabin interiors is the absence of high-performance materials that are EASA and FAA-certified. Both parties have agreed to jointly develop and test new material grades in accordance with EASA and FAA criteria.

Source: Press Release

Website: LINK