Phoenix Analysis and Design Technologies (PADT) has announced it’s opening a 3D printing factory, using Carbon’s Digital Light Synthesis technology and production system to create 2,000-5,000 parts on-demand weekly.

Phoenix Analysis and Design Technologies (PADT), the Arizona-based provider of Product Development and Rapid Prototyping services, has announced it’s opening an On-Demand Manufacturing facility with Carbon — believed to be a first in the Southwest of America.

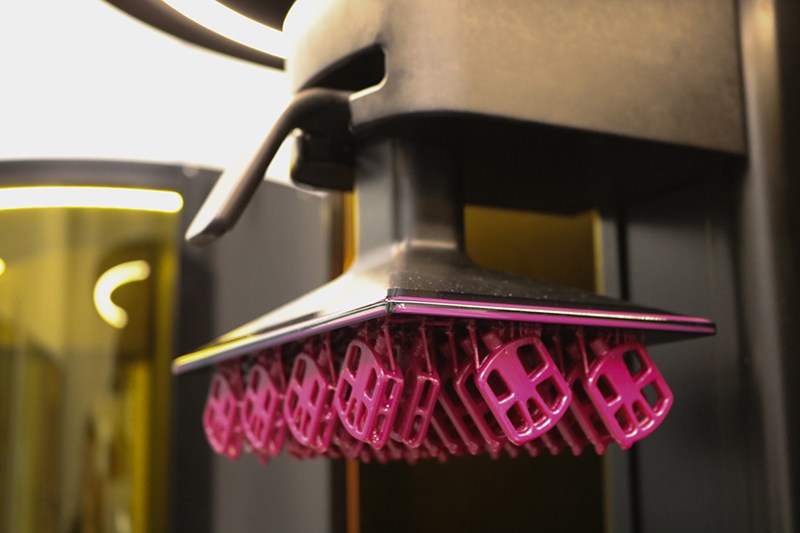

PADT is a certified Production Partner of the Silicon Valley-based 3D printing company and manufacturer, Carbon. This new tie-up means that, using Carbon’s printers, PADT can create between 2,000 to 5,000 cost-effective, quality production plastic parts on-demand in one week.

Rey Chu, co-founder and principal of PADT, is excited by this prospect, saying: “Since we started in 3-D Printing almost 25 years ago, we have dreamed of the day that we could use additive manufacturing to move beyond prototyping and deliver production parts to our customers when they need them, the way they need them… Carbon’s (Digital Light Synthesis) technology has made this possible by giving us a faster process that creates parts with the same properties as injection molding.”

PADT Can Now Deliver 3D Printed Parts in Just One Week

PADT is using Carbon’s Digital Light Synthesis technology and production system. During the testing period, Eric Miller, principal and co-owner of PADT, said that the company could produce 20 parts every three hours with the three Carbon printers on site.

The production parts which will be printed by PADT include low volume, specialized components predominantly for the medical and automotive industries. The company explains that no molds are required thanks to 3D printing and fully-assembled complex shapes can be created in one go.

Miller adds that it’s now possible to 3D print parts as they’re needed, rather than in bulk. This means companies can order only as much as they need at any time. Better yet, they can expect to receive the parts in one week, rather than three months as with injection molding processes.

“Our goal is to deliver true, scalable digital fabrication across the globe, enabling creators to design and produce previously unmakeable products, both economically and at scale… PADT has a long history in the industry and a strong reputation for engineering excellence. We’re thrilled to have them as a certified Carbon production partner,” said Dana McCallum, head of Production Partnerships at Carbon.

PADT’s Digital Manufacturing Facility is now open, visit the website to find out more.

Source: AZ Big Media

Website: LINK