Forging a new path for more accessible metal 3D printing, Desktop Metal has been granted patents for its Separable Supports technology. Designed to make metal 3D printing more accessible and safer, the tech means multi-material metal printing and hand-removable supports.

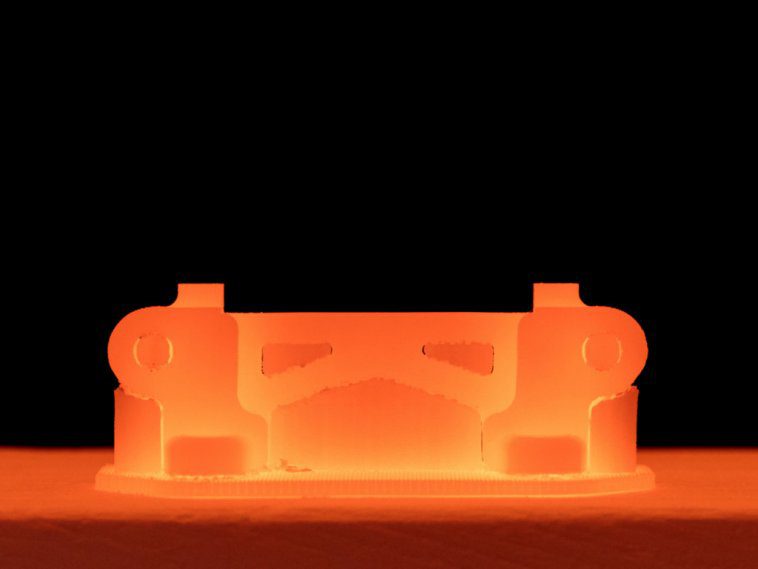

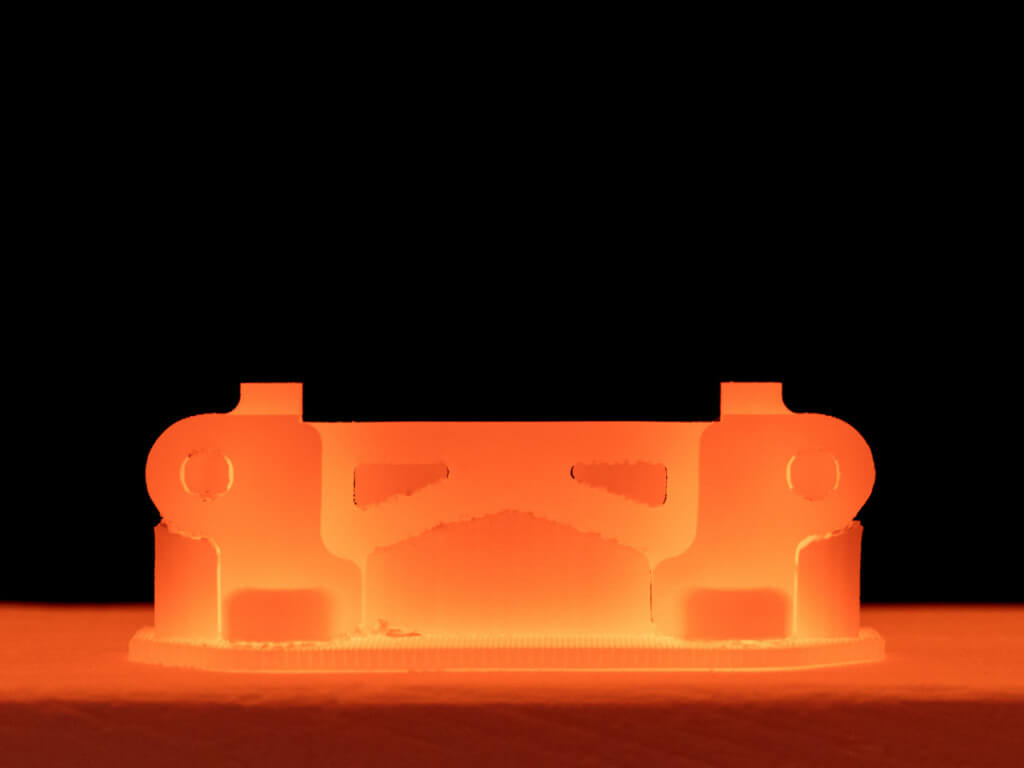

Desktop Metal, a Massachusetts-based company that has developed office and mass-production level metal 3D printers, has just been granted the patents for its proprietary Separable Supports technology. The technique is the company’s way of printing easy-to-remove support structures from parts that have been printed on its Studio System (and Production System, coming later this year).

The Desktop Metal Studio System is the first of its kind — a metal 3D printing system safe for use in workshop-office environments. It includes a printer, de-binder and sintering furnace which not only make the metal 3D printing process safer for an office or non-specialized environment, but faster too.

According to Jonah Myerberg, Chief Technology Officer and Co-Founder of the company:

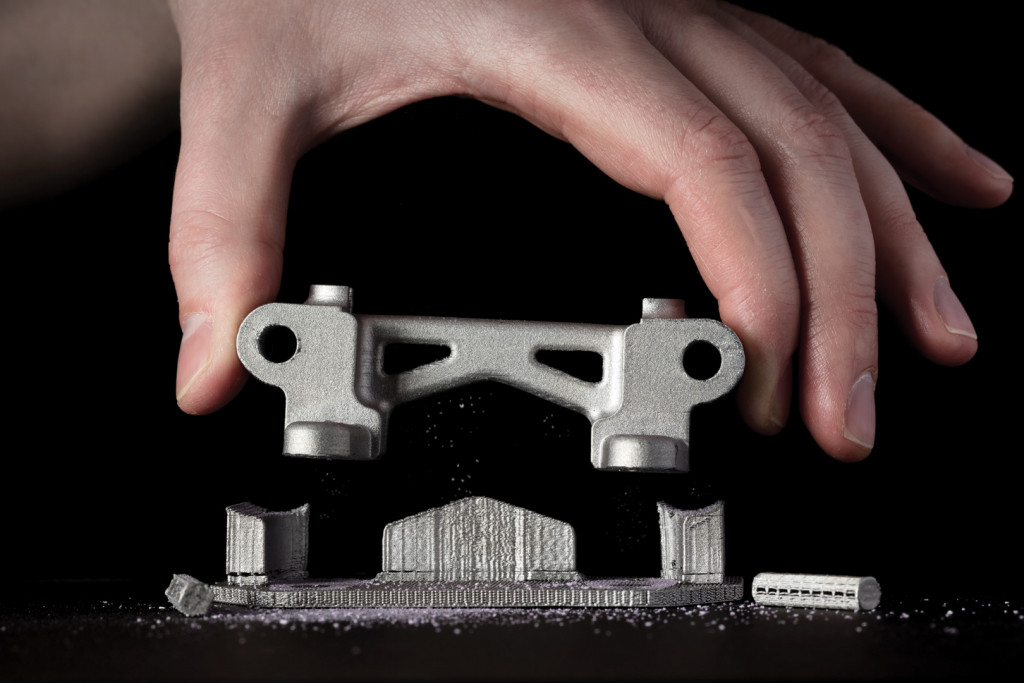

“As a company driven by invention, we are committed to both innovating and protecting our technology through strategic intellectual property achievements. The technological innovation in these patents enables users, for the first time, to print large metal parts with complex geometries that can be easily removed from their support structures by hand or to print metal objects with separable interlocking structures.”

Desktop Metal’s Patented Support System

Whilst more traditional laser power bed methods for 3D printing tend to be restricted to a single source material, the Desktop Metal innovation allows creators to benefit from the use of multiple materials during the printing process.

In essence, creators can now print support structures which do not bond to the final part. Instead, they consolidate during sintering with the part, resulting in high dimensional accuracy. The support structures can then simply be removed by hand.

“We believe the benefit of this technology covered by the patents will enable substantially increased adoption of metal AM,” adds Myerberg.

Desktop Metal now holds a wide variety of patented technologies. In addition, the company’s existing pending patent applications cover more than 200 innovations.

Source: Desktop Metal & TCT Magazine

Website: LINK