With the expiration of key patents, availability of advanced digital modeling software, and improved hardware, additive manufacturing is on the verge of radically changing how products are designed, made and maintained. But a lack of understanding of its fundamental principles, applications, and business implications is proving to be a barrier to broader adoption.

To help professionals and organizations realize the potential of 3D printing — and perhaps accelerate its use — the Massachusetts Institute of Technology and aerospace company Boeing are collaborating on a new online course for professionals. It’s called “Additive Manufacturing for Innovative Design and Production”.

“Our educational collaboration with MIT encourages employees to grow professionally and develop new manufacturing skills,” says Michael Richey, chief learning scientist at Boeing.

“Through a combination of industry and academic expertise, the additive manufacturing curriculum will equip employees with knowledge of the fundamentals of 3D printing, which has the potential to catalyze widespread change across the manufacturing industry.”

The nine-week course will teach critical skills that prepare employees to implement AM in their organizations. The course explains leading AM technologies for polymers, metals, and advanced materials; addresses design for AM via both engineering principles and computational design; and includes quantitative models for assessing the cost and value of components made by AM.

MIT and Boeing Hope to Jumpstart Career Learners in AM Processes

Mike Vander Wel, a production engineering chief engineer at Boeing, says the company has been involved in AM for nearly three decades. They regularly use it to prototype, test, and manufacture small parts for some aircraft.

While new graduates are entering the workforce with a basic knowledge of AM technology, more experienced employees have little or no exposure to it. The MIT-Boeing collaboration is designed to jumpstart career learners on AM processes, applications, and analyses.

Aside from its benefits to business, MIT and Boeing view AM as an opportunity to improve job satisfaction as well.

“To me, accomplishment equates to job satisfaction,” says Vander Wel. “Upon completion of the course, learners will be able to develop additive applications and work collaboratively to solve problems, which will be deeply gratifying.”

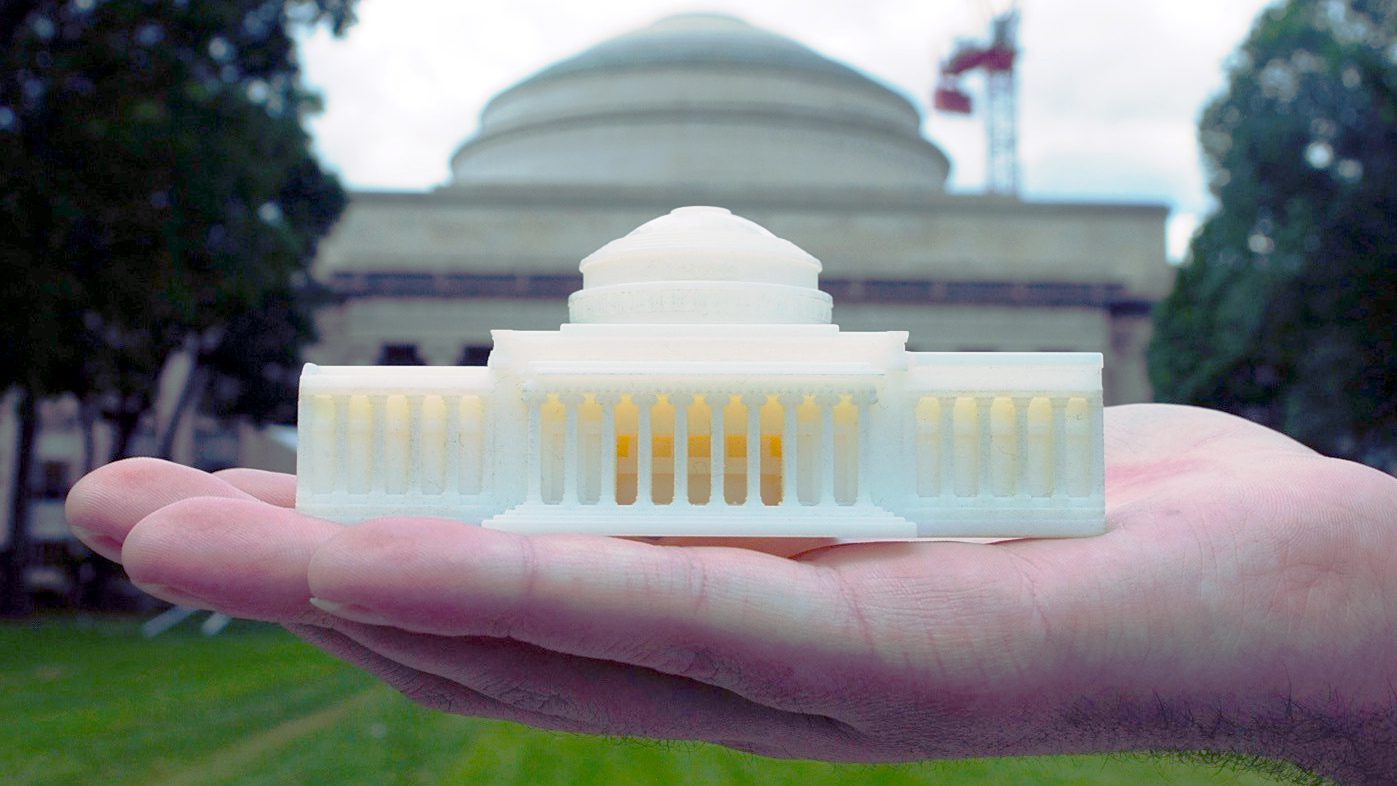

Also part of the course from MIT and Boeing is a 3D printed kit used to enrich the learning experience. Similar to a textbook, the kit is used as a reference throughout the course. The kit has metal and polymer parts made by industry-relevant 3D printing processes, including stereolithography, multijet fusion, and direct metal laser sintering. The parts interlock to form a model of MIT’s iconic Building 10 dome.

The Additive Manufacturing for Innovative Design and Production course starts on 30 April, and registration is open now. For more information, visit the course website.

Website: LINK